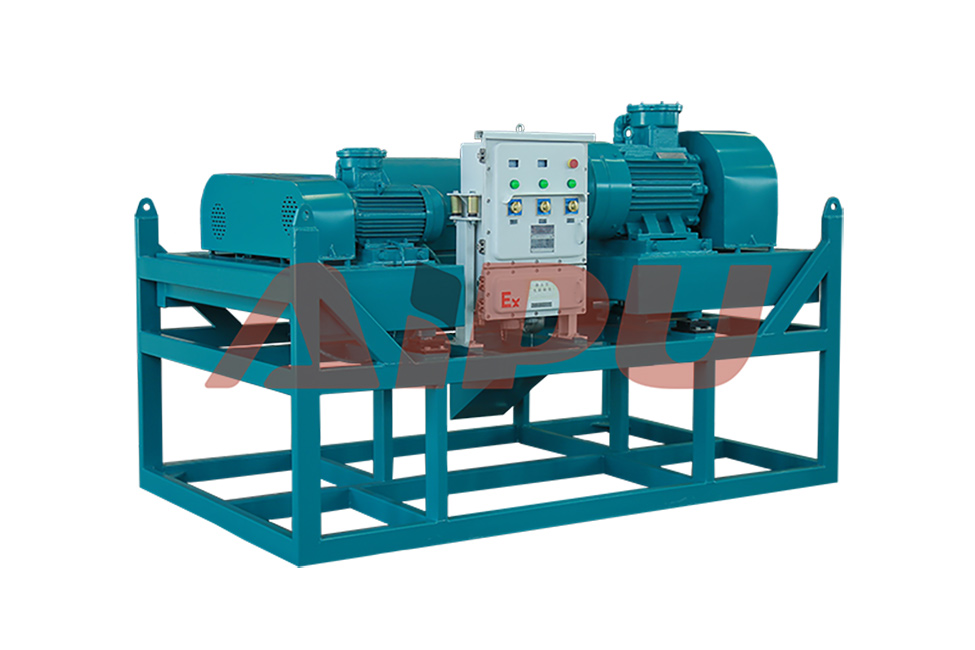

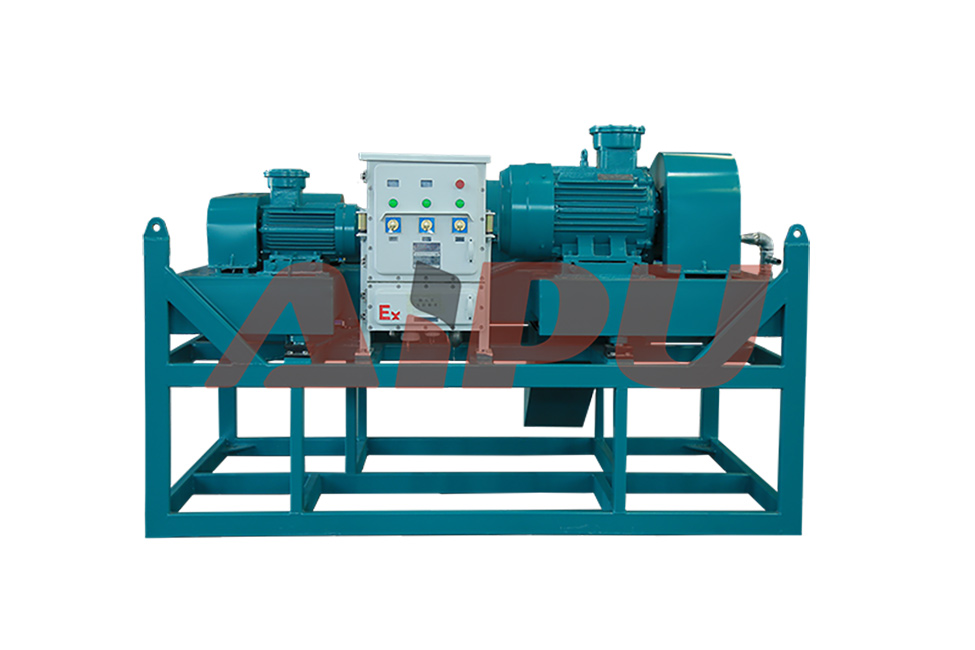

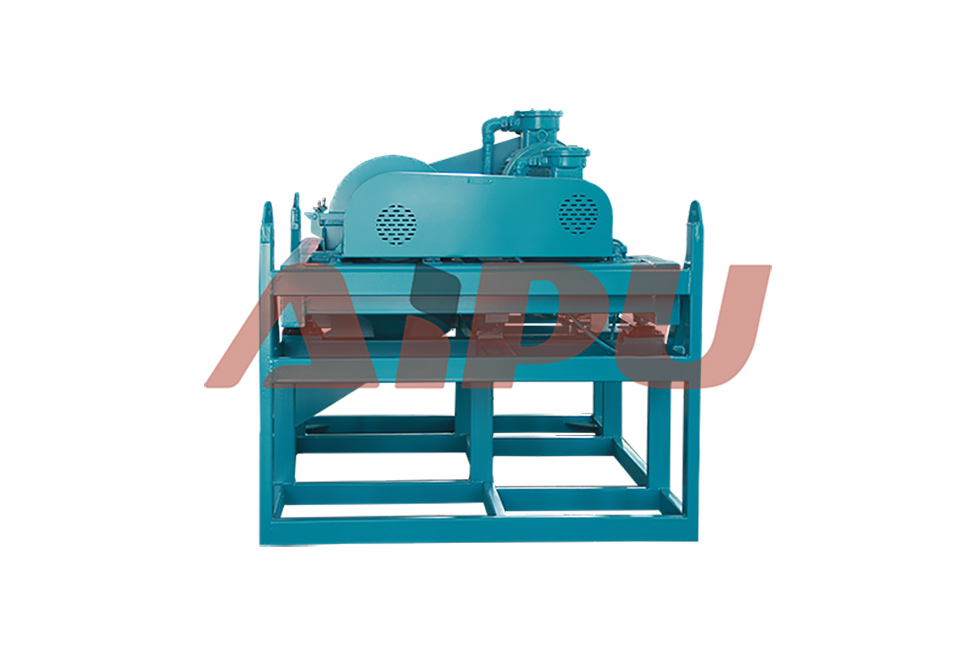

Decanter Centrifuge

What is Decanter Centrifuge?

Decanter centrifuge is used to separate drilling cuttings out of drilling mud as the 5th phase cleaning in the whole solids control system. It is also referred to centrifuge decanter or decanting centrifuge. AIPU decanter centrifuge can provide a great performance for fine solids separation, or barite recovery in drilling fluids system.

Product Description

Decanter centrifuge is an important component of solids control. AIPU centrifuges achieve effective fine solids separation, or barite recovery in drilling fluids system in onshore/offshore O&G drilling, drilling waste management, as well as the dewatering process. We supply various options of decanter centrifuge to meet certain client’s demand, including middle speed centrifuge, high speed decanters, VFD high speed centrifuge, hydraulic drive centrifuges. Centrifuges are operated after desilter or mud cleaner to separate particles between 2 to 7 microns. And for centrifuge feeding pump, there are 2 options mainly, the screw pump and submersible slurry pump. Depending on users’ preference and actual condition, we’ll propose an optimal one.

Application Effects and Advantages

- High treating capacity

- Stable performance

- Reliable material with durable quality

- Duplex S.S2205 is optional

- Little spare parts cost

- Easy operation with less maintenance

- Anti-abrasive&anti-corrosive with Tungsten carbide employed

- Longer service life

- Cost-efficient solution for all users

- Special design will be employed according to users’ preference

Specifications and Parameters

| Model | APLW450×842N | APLW450×1000N | APGLW355×1258D-N | APGLW450×1258D-N | APGLW530×1320D-N |

|---|---|---|---|---|---|

| Drum Dia. | φ450mm | φ450mm | φ355mm | φ450mm | φ530mm |

| Drum Length | 842mm | 1000mm | 1258mm | 1258mm | 1320mm |

| Lambda Ratio | 1.9 | 2.2 | 3.5 | 2.8 | 2.5 |

| Drum Shape | Conical | ||||

| Speed | 1800rpm | 2200rpm | 3200rpm | 3000rpm | 2800rpm |

| Main Motor | 22Kw | 30Kw | 30Kw | 37Kw | 55Kw |

| Accessory Motor | 5.5Kw | 7.5Kw | 7.5Kw | 11Kw | 11Kw |

| Max. Capacity | 40m³/h | 50m³/h | 35m³/h | 60m³/h | 65m³/h |

| Separation Point | 5~7microns | 2-5microns | |||

| Separation Factor | 815G | 1215G | 2035G | 2250G | 1817G |

| Suggesting Pump | 4kw (submersible) | 5.5kw(submersible) | 7.5kw(submersible) | ||

| Reference Dimension | 2600×1550×1650mm | 2750×1550×1700mm | 2900×1480×1650mm | 2900×1550×1650mm | 3300×1700×1750mm |

| Weight | 3000kg | 3200kg | 3000kg | 3200kg | 4000kg |

More Options

Customizable Options for APLW Mud Decanter Centrifuge

Facing the international market, based on the actual needs of users, AIPU provides flexible configuration for customers. The following are the main optional parameters:

- Electrical System - Customizable

- Material - Material optional (Typically refers to stainless steel grade or other material specifications)

- Certifications - ATEX, IEC, DGMS, UL etc. certificates are optional

- Surface Color

Additional Optional Component

Control Cabinet - Pressurized EX Proof VFD (Variable Frequency Drive) control cabinet available.

Why Choose Aipu Solid Control?

As the top solid control manufacturer in China, Aipu Solid Control always puts customer needs first. We firmly believe that technology can create the future, but service is the bridge that turns technical strength into real value for customers. Aipu Control insists on providing high-quality products and services. And it is an honor to be your ideal global supplier of drilling fluid treatment equipment. Looking forward to serving you.

Our Commitment

We are committed to delivering:

- High-quality, reliable equipment

- Competitive pricing

- Responsive technical support

- Customized solutions

- Timely delivery

Frequently Asked Questions

What is the typical delivery time for your equipment?

We offer expedited shipping options for urgent requirements.

Do you provide installation and training services?

Yes, we provide comprehensive installation supervision, commissioning, and operator training services. Our technical team can assist on-site or provide detailed remote guidance and documentation.

How durable are your centrifuges in harsh environments?

Our equipment is built for durability with high-quality materials, corrosion-resistant coatings, and robust construction. They perform reliably in extreme conditions including desert heat, marine environments, and arctic temperatures.

Can you customize equipment for specific project requirements?

Absolutely. We specialize in custom solutions including specific dimensions, special materials, unique configurations, and integration with existing systems. Share your requirements and we'll provide a tailored solution.

How do you handle spare parts and maintenance?

We maintain a comprehensive inventory of spare parts and offer worldwide shipping. Our online parts catalog makes ordering easy, and we provide detailed maintenance manuals and video tutorials for all equipment.

Have more questions? We're here to help!

Contact Our ExpertsRequest a Quotation

Please provide your details and we'll get back to you soon with the best solution for your needs.